Core Operations & Technological Advancements

Placer Gold Exploration Techniques

Placer gold deposits, commonly found in alluvial environments shaped by rivers or glacial activity, require a multi-disciplinary exploration approach. We integrate geology, geophysics, geochemistry, and shallow drilling to identify and assess target zones with technical precision.

- 🗺️ Geological Survey: Delineation of paleo-channels and sediment stratigraphy using field mapping and facies analysis.

- 📡 Geophysical Methods: ERT and seismic refraction for profiling bedrock troughs; magnetometry for structural inference.

- 🧪 Geochemical Sampling: Analysis of heavy mineral concentrates, gold grain morphology, and trace element anomalies.

- 🛠️ Shallow Drilling: Auger, RC, and sonic drilling with trench verification to assess deposit continuity and grade.

- 🏺 Heavy Mineral Testing: Traditional panning for quick in-field assessment of grain size, shape, and count.

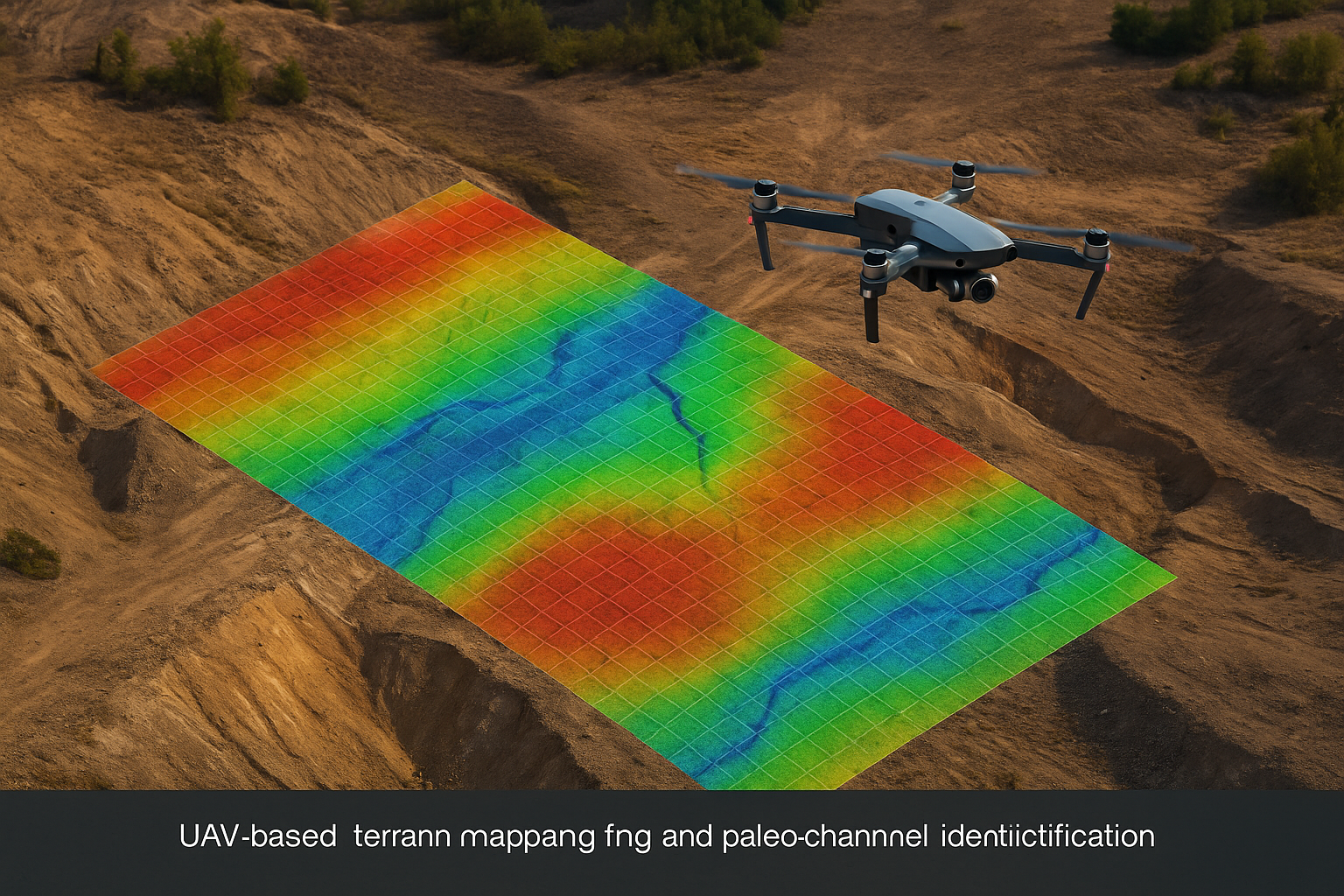

- 🚁 Remote Sensing & UAV: High-resolution drone photogrammetry and LiDAR modeling for paleo-hydrological reconstruction.

- 🧭 3D Geological Modeling: Integration of all data into Surpac, Vulcan, or GIS for volumetric estimation and planning.

Figure: UAV-based terrain mapping and paleo-channel identification in placer fields

Mining Operations & Gold Recovery Technologies

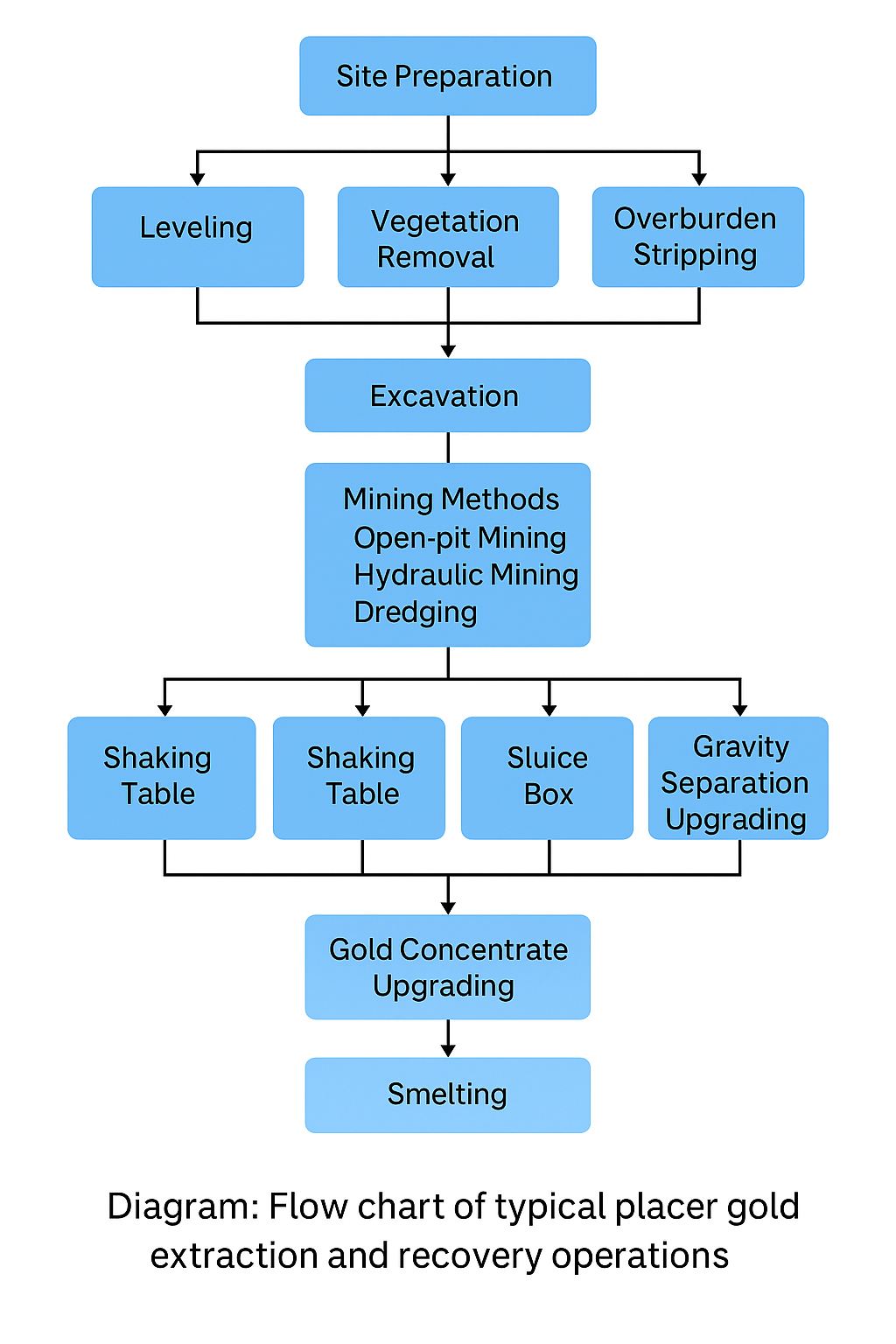

⛏️ Mining Methods

- Open-Pit: Bulk extraction using excavators; ideal for shallow, laterally extensive deposits.

- Hydraulic Mining: Water cannon-based sediment mobilization; now rarely used due to regulation.

- Dredging: Historic use of bucketline dredges in submerged or deep placer zones.

⚖️ Gravity Separation

- Sluice Systems: Carpet-lined channels to separate gold via density-driven flow.

- Shaking Tables: Ideal for fine-grained material; uses vibration and stratification.

- Trommel + Sluice: Combines screening and flow-based recovery for high-volume operations.

🔁 Concentrate Upgrading

- Centrifugal Concentrators: Falcon & Knelson for ultra-fine gold recovery using high G-force.

- Smelting: Final refinement into dore bars using flux-based melting in induction furnaces.

🌱 Environmental Compliance

- Adherence to BC’s Placer Tenure and NoW permit process.

- Use of sedimentation ponds and water recycling systems.

- Mandatory land restoration and revegetation post-mining.

🔬 Modernization & Smart Mining Systems

- 🚁 Autonomous UAV Mapping: High-resolution GPS/LiDAR-integrated drone mapping for terrain modeling.

- 🧰 Integrated Mobile Plants: Modular, trailer-mounted systems with trommel, concentrator, and sluice integration.

- 📈 Real-Time Monitoring: Particle size/gold content sensors integrated for on-site optimization.

- ♻️ Green Innovations: Closed-loop water systems, dry tailings disposal, and low-impact site designs.

Smart Mining: Next-gen mobile recovery systems with onboard analytics and minimal footprint